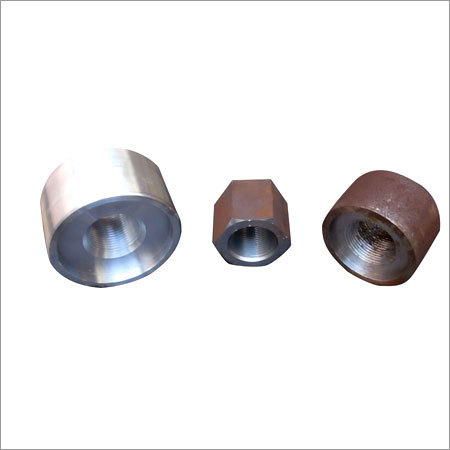

Stainless Steel Nuts

Stainless Steel Nuts Specification

- Diameter

- M3 to M36, Custom sizes on request

- Head Size

- Available in all Metric & Inch sizes

- Head Type

- Hexagonal

- Standard

- DIN, ISO, ASTM, or as specified

- Material

- Function

- Secure fastening and joining of materials

- Weight

- Standardized as per size, typically light weight

- Surface

- Polished, Smooth Finish

- Feature

- Corrosion Resistant, High Strength, Durable

- Packaging

- Boxed or bulk, as per customer requirement

- Temperature Range

- -50°C to +800°C

- Thread Type

- Metric, Unified, and other custom threads

- Application

- Automotive, Construction, Machinery, Marine, and General Industrial Use

- Finish Type

- Self-colored, Passivated, or Electro Polished

- RoHS Compliance

- Yes

- Tensile Strength

- Min 515 MPa (SS304)

- Hardness

- 140-220 HV (varies by grade)

Stainless Steel Nuts Trade Information

- Payment Terms

- Cash on Delivery (COD), Western Union, Paypal, Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Delivery Point (DP), Cash Against Delivery (CAD), Cash Advance (CA), Telegraphic Transfer (T/T), Days after Acceptance (DA), Cash in Advance (CID), Cheque

- Main Domestic Market

- North India

About Stainless Steel Nuts

Since our inception in 1983, we are able to manufacturer, export and supplier a broad range of Steel Nuts. These nuts are are highly demanded for fastening purposes. The offered nuts are manufactured with utmost perfection by our experienced professionals. Acclaimed for its rugged design and non slippery surface, these Steel Nuts can be bought from us at competitive price.

Key Feature:

- Accurate dimension

- Superior finish

- Easy to fit

- Resistant to corrosion

Engineered for Diverse Applications

Stainless steel nuts are suitable for demanding environments such as automotive, maritime, industrial machinery, and construction projects. Their robust hardness range and high tensile strength ensure reliable, secure fastening even under harsh conditions, offering longevity and consistent performance.

Versatile Thread and Finish Options

Choose from metric, unified, or bespoke thread types to match your project requirements. Nuts are available in a variety of finishesself-colored, passivated, or electro-polishedfor both functional protection and aesthetic appeal. RoHS-compliant and standardized to international norms, they are tailored to suit every request.

FAQs of Stainless Steel Nuts:

Q: How are stainless steel nuts manufactured and finished?

A: Stainless steel nuts are precision-manufactured using high-grade materials like SS304 or SS316. After forming, they undergo finishing processes such as passivation or electro-polishing, creating a smooth, polished surface that improves both corrosion resistance and durability.Q: What applications are these stainless steel nuts ideal for?

A: These nuts are designed for versatile use in automotive, construction, marine, mechanical, and industrial settings. Their corrosion resistance and strength make them suitable for both indoor and outdoor environments, even in areas exposed to moisture or fluctuating temperatures.Q: When should I choose a custom thread or finish option?

A: Custom threads and finishes are recommended when standard metric or unified threads dont meet your application requirements, or when a particular finish enhances performance or visual appeal in your project. Customization ensures optimal compatibility and protection against specific environmental factors.Q: Where are these nuts usually installed or used?

A: They are commonly installed in vehicles, heavy machinery, building structures, marine vessels, and general industrial assemblies where secure, corrosion-resistant fastening is essential.Q: What is the process for bulk or customized packaging?

A: Packaging can be tailored to your needs, with options for boxed or bulk formats. Once your order specifications are received, nuts are carefully packed to protect the surface finish and facilitate efficient storage or transport.Q: How do these stainless steel nuts benefit end users over standard alternatives?

A: They offer superior corrosion resistance, robustness, and a wide temperature tolerance range. End users benefit from longer service life, reduced maintenance, and reliable performance, even in harsh conditions.Q: What standards do these nuts meet and why is this important?

A: Our stainless steel nuts comply with DIN, ISO, and ASTM standards, ensuring consistent quality, precise sizing, and interoperability in global projects. This adherence helps guarantee reliability and safety in critical applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Nuts Category

snatch block assembly h-12

Price 9800 INR / Piece

Minimum Order Quantity : 1 Number

Function : Used for lifting and rigging applications

Material : Steel

Standard : Industrialgrade construction

Surface : Painted yellow coating for corrosion resistance, Other

PULLEY BLOCK ASSEMBLY

Price 9600 INR / Piece

Minimum Order Quantity : 1 , , Number

Function : Lifting and load handling

Material : Other, Cast iron and steel

Standard : ISI certified

Surface : Powdercoated yellow finish, Other

"We are inviting more inquiries from North India."

Send Inquiry

Send Inquiry