Cnc Turned Components

Cnc Turned Components Specification

- Weight

- 5 grams to 5 kilograms (as per design)

- Accuracy

- 0.01 mm

- Hardness

- Up to 62 HRC

- Method

- CNC precision turning

- Load Capacity

- Depending on material & size (design specific)

- Coating

- Zinc plating, Nickel plating, None (as required)

- Size

- 3 mm to 200 mm diameter (customized length)

- Thread Type

- Metric/UNC/UNF/Customized

- Shape

- Customized as per drawing (round, hexagonal, etc.)

- Spindle Speed

- 5004000 rpm

- Cutting Speed

- 60250 m/min (material dependent)

- Machine Type

- CNC Turning Machine

- Type

- Turned Component

- Material

- Stainless Steel, Brass, Mild Steel, Aluminum

- CNC

- Yes

- Tolerance

- 0.01 mm

- Surface

- Polished/Precision-machined

- Use

- Industrial machinery, automation, automotive

- Application

- Precision turning, assembling mechanical units

- Usage & Applications

- Machinery parts, shafts, fittings, spacers, bushings

- Corrosion Resistance

- High (subject to material & coating)

- Production Capacity

- Up to 100,000 pieces per month

- Finish

- Smooth, burr-free, mirror finish available

- Lead Time

- 24 weeks, depending on quantity and complexity

- Minimum Order Quantity

- 100 pieces

- Inspection

- 100% QC, CMM and profile projectors used

- Customization

- Available as per drawing or sample

- Packaging

- Individually packed or in bulk, on request

Cnc Turned Components Trade Information

- Main Domestic Market

- North India

About Cnc Turned Components

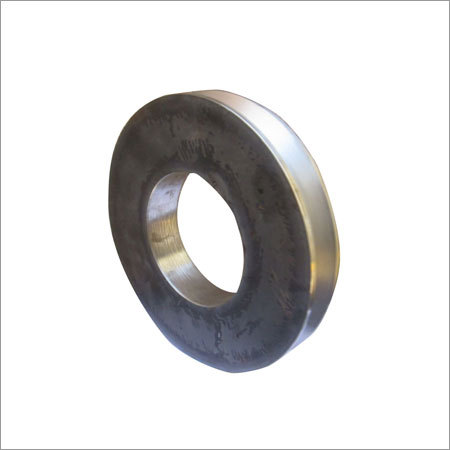

Relying over our wide domain expertise, we are engrossed in offering a supreme quality range of Cnc Turned Components. These components are extensively used as spare part in all CNC machines and other devices for fastening purposes. The offered components are manufactured under the strict vigilance of our experienced professionals optimal quality metal alloys and sophisticated technology. Further, these Cnc Turned Components are tested on defined quality parameters that are available with us in different sizes at the most budgeted prices.

Key Features:

- Sturdy design

- Excellent gripping

- Easy to handle

- Non-abrasive surface

Precision and Quality Assurance

All components undergo stringent 100% inspection protocols, utilizing advanced CMM and profile projectors to ensure flawless precision with tolerances up to 0.01 mm. Our commitment to quality stands at every stage, from raw material verification to final packaging, guaranteeing smooth, burr-free, and mirror-finished parts ideal for demanding industrial applications.

Customization for Diverse Applications

We offer extensive customization options based on customer drawings or samples. Components can be crafted in various shapes (round, hexagonal, or as per design) and finished with coatings like zinc or nickel. This versatility caters to machinery parts, fittings, spacers, shafts, bushings, and more, supporting wide industry requirements.

Efficient Production and Packaging

With our monthly production capacity reaching up to 100,000 pieces and flexible lead times of 24 weeks, we accommodate both large and small scale demands. Individual or bulk packaging options are available upon request, guaranteeing each product reaches you securely, regardless of quantity.

FAQs of Cnc Turned Components:

Q: How are your CNC turned components inspected for quality?

A: Each component is subjected to 100% quality control, utilizing CMM (Coordinate Measuring Machine) and profile projectors. This ensures every part meets tight tolerances and high standards, resulting in burr-free, smooth, and mirror-finished pieces.Q: What customization options do you offer for CNC turned components?

A: We customize components as per your technical drawings or samples. This includes options for material (such as stainless steel, brass, mild steel, or aluminum), shape (round, hexagonal, or custom), surface coatings (zinc, nickel, or uncoated), threads (Metric, UNC, UNF, or custom), and specific tolerances.Q: When can I expect delivery after placing an order?

A: Lead times typically range from 2 to 4 weeks based on the order quantity and complexity of the component design. For urgent needs, we recommend contacting us directly to discuss expedited options.Q: Where are your CNC turned components manufactured?

A: All our CNC turned components are manufactured in India, leveraging state-of-the-art CNC turning machines and a skilled workforce to deliver consistent, high-quality products for global requirements.Q: What is the minimum order requirement for these components?

A: The minimum order quantity for our CNC turned components is 100 pieces. This applies to both standard and customized orders, ensuring we can cater to both small-scale and larger industrial demands.Q: What industrial sectors benefit from your CNC turned components?

A: Our components are widely used in industrial machinery, automation systems, automotive assemblies, and a variety of engineering applications that demand precision and reliability.Q: What is the typical usage process for your CNC turned components?

A: After delivery, components are ready for immediate integration into your assemblies or machinery. Each part is designed and finished for easy installation, whether its for shafts, spacers, bushings, or mechanical fittings.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in CNC Turned Components Category

CNC Turned Steel Components

Size : Customized: Diameter 5 mm to 150 mm, Length up to 500 mm

Coating : Zinc Plated / Black Oxide / Nickel Plated (as required)

Load Capacity : Depends on size & designup to 5000 kgf

Surface : Other , Polished / Machined Surface

Material : Alloy Steel / Mild Steel / Carbon Steel

Application : Automotive, Aerospace, Industrial Automation

"We are inviting more inquiries from North India."

Send Inquiry

Send Inquiry