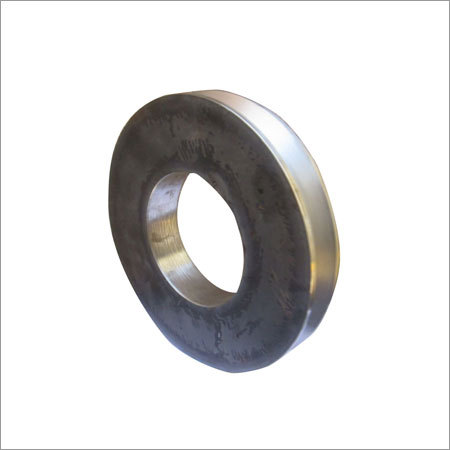

CNC Turned Steel Components

CNC Turned Steel Components Specification

- Accuracy

- 0.01 mm

- Thread Type

- Metric / Imperial (as specified)

- Spindle Speed

- Up to 4000 rpm

- Shape

- Cylindrical / Custom Profile

- Machine Type

- Advanced CNC Turning Center

- Size

- Customized: Diameter 5 mm to 150 mm, Length up to 500 mm

- Load Capacity

- Depends on size & designup to 5000 kgf

- Cutting Speed

- Up to 300 m/min

- Coating

- Zinc Plated / Black Oxide / Nickel Plated (as required)

- Hardness

- 35-50 HRC (Depending on material and heat treatment)

- Method

- CNC Turning / Finishing / Quality Inspection

- Weight

- Variable as per design, typically between 30g to 10kg

- Type

- Custom CNC Turned Component

- Material

- Alloy Steel / Mild Steel / Carbon Steel

- CNC

- Yes

- Tolerance

- 0.01 mm

- Surface

- Polished / Machined Surface

- Use

- Mechanical assemblies, industrial machinery

- Application

- Automotive, Aerospace, Industrial Automation

- Usage & Applications

- Used in high-precision engineering, shaft assemblies, coupling parts, and fixtures

- Quality Control

- 100% dimensional inspection, Material test certificate provided

- Corrosion Resistance

- High, with optional additional coatings

- Machinability

- High, suitable for complex geometries

- Packaging

- Wooden crates / Bubble wrap / Carton boxes

- Temperature Resistance

- -40°C to +200°C (depends on grade)

- Production Capacity

- 5000 pieces per month

- Finish

- Deburred and burr-free edges

- OEM Service

- Available as per drawing and requirements

- Lead Time

- 2-4 weeks for bulk order

CNC Turned Steel Components Trade Information

- Payment Terms

- Delivery Point (DP), Cash Against Delivery (CAD), Cash on Delivery (COD), Letter of Credit (L/C), Paypal, Western Union, Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Domestic Market

- North India

About CNC Turned Steel Components

Established in 1983, our organization is considered as the leading manufacturer, exporter and supplier of Hook Pulley Block. The provided block is especially designed to support movement or change of direction of belt and cable attached to it. The offered block is manufactured by utilizing the best grade metal alloy and progressive methodology. To meet the specific needs of our clients, this Hook Pulley Block is available with us in different specifications.

Features:

- Smooth edges

- Flawless finish

- Sturdiness

- High load bearing ability

Precision and Quality Assured

Using state-of-the-art CNC turning technology, every steel component is produced with remarkable accuracy, up to 0.01 mm tolerance. Each unit is checked through a comprehensive, 100% dimensional inspection. This rigorous process ensures defect-free, highly reliable parts, making them ideal for demanding mechanical and industrial applications.

Custom Solutions for Diverse Applications

Whether your requirements involve automotive assemblies, aerospace projects, or industrial automation, these CNC turned components are engineered for versatility. We provide customized sizing, threading (metric or imperial), and multiple material/coating options to fit your specific needs. OEM service and complex geometry machining are available based on provided drawings.

Durable, Safe, and Ready to Install

Finished with burr-free edges and robust coatings such as zinc plating or black oxide, each component is suited for harsh industrial environments with temperature resistance from -40C up to 200C. Secure packaging in wooden crates, bubble wrap, or carton boxes ensures your parts arrive safely and ready for integration.

FAQs of CNC Turned Steel Components:

Q: How are the CNC Turned Steel Components manufactured?

A: These components are produced using advanced CNC turning centers, which allow high-precision turning and finishing. The process involves machining alloy, mild, or carbon steel to custom specifications, followed by deburring, surface finishing, and a thorough quality inspection for consistent accuracy and performance.Q: What quality control measures are in place to ensure part accuracy and reliability?

A: We perform 100% dimensional inspection on every component, verifying tolerances up to 0.01 mm. Additionally, material test certificates are provided, and each part is carefully finished and visually inspected to guarantee burr-free, fully compliant assemblies.Q: When can I expect delivery for bulk orders?

A: For large quantities, standard lead times are between 2 to 4 weeks, depending on the complexity and specific customizations required. Our monthly production capacity enables us to efficiently fulfill orders up to 5000 pieces.Q: Where are these components typically used?

A: These CNC turned steel components are widely employed in mechanical assemblies, industrial machinery, and sectors like automotive, aerospace, and automation. Their high precision and reliability make them suitable for shaft assemblies, coupling parts, and fixtures requiring robust performance.Q: What are the benefits of choosing these components for my application?

A: Benefits include exceptional dimensional accuracy, high machinability for complex profiles, robust corrosion and temperature resistance, and a range of customized finishes and coatings. OEM services are also available to precisely match your projects requirements.Q: What customization options are available in terms of sizing and coatings?

A: You can specify dimensions between 5 mm to 150 mm in diameter and up to 500 mm in length, with variable weights. Coating options include zinc plating, black oxide, nickel plating, or customized finishes to meet corrosion and appearance demands.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in CNC Turned Components Category

Cnc Turned Components

CNC : Yes

Method : CNC precision turning

Usage & Applications : Machinery parts, shafts, fittings, spacers, bushings

Application : Precision turning, assembling mechanical units

Weight : 5 grams to 5 kilograms (as per design)

Type : Other, Turned Component

"We are inviting more inquiries from North India."

Send Inquiry

Send Inquiry